Unique collaboration at ZELTWANGER

At ZELTWANGER, 20 component manufacturers are currently working together on the VDMA joint project for Open Platform Communications Unified Architecture (OPC UA)

ONE LANGUAGE FOR EVERYONE: ESPERANTO FOR MACHINES

Behind the screens in the production hall of the Dußlingen-based company ZELTWANGER, we are working on the standard of tomorrow: With the OPC UA Demonstrator, VDMA Robotics + Automation is presenting a communication standard that enables standardized and platform and manufacturer-independent digital networking in production. The Demonstrator will be launched at automatica 2018.

Open communication standards are essential for the production of the future. OPC UA enables standardized and platform and manufacturer-independent collaboration between different machines and systems and ensures cross-manufacturer compatibility

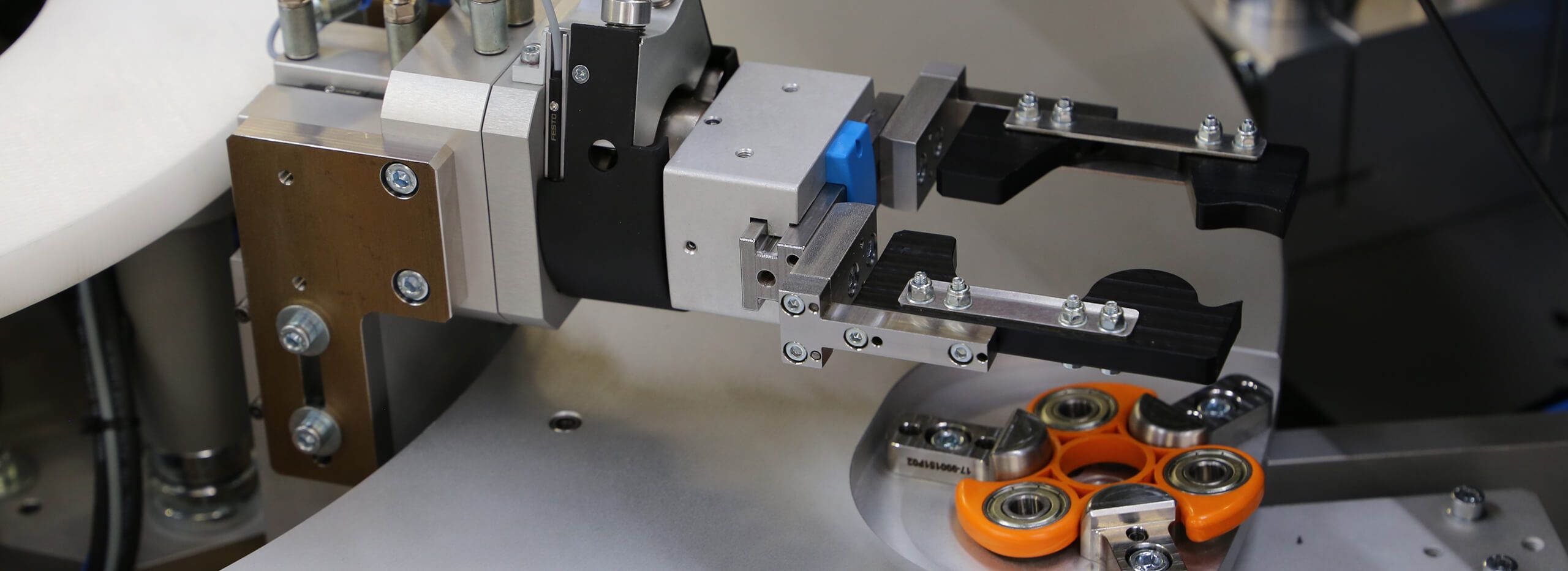

The entire realization of the VDMA OPC UA project has also been manufacturer-independent: Over 20 component manufacturers, system integrators, and software specialists are currently working together on the Demonstrator at the ZELTWANGER company premises in Dußlingen. A rotary indexing table, axes, and grippers, as well as image processing systems and robots are integrated into an X-CELL. Condition monitoring is cloud-based, regardless of the manufacturer and robot type. “It is fascinating to work side by side with other well-known companies on a joint project like this one,” says Rainer Paul, Product and Market Manager at ZELTWANGER.

Interoperable, manufacturer-independent, skill-based: To make the vision of machine-to-machine communication a reality, VDMA Robotics + Automation launched several initiatives in early 2017 to develop data models for the standardized and open communication standard OPC UA. So-called “companion specifications” for OPC UA, which represent the industry and application-specific data models, are developed in VDMA working groups. “We are literally building together on the foundation of future production,” says Paul.

The OPC UA Demonstrator at automatica 2018 combines use-case control and condition monitoring and makes the potential of OPC UA tangible. And this is not abstract, but very specific: Fidget Spinners are mounted on a fully automated assembly system. “After its premiere at automatica, we will continue to develop the specification in-house together with the VDMA partner companies,” says Paul. The ZELTWANGER company premises will remain the permanent location for the VDMA “Future in Production” joint project.

More articles

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de