End-of-Line Test Systems FOR HEAT EXCHANGERS

Our flexible and reliable end-of-line testing systems are specially tailored to the requirements of heat exchanger production. Benefit from scalable systems that elevate your testing processes.

The benefits to you

Use advanced EOL testing systems to make your production efficient and future-proof.

Modular and scalable

Flexibly adapt your systems to different quantities.

Fully integrable

Transform your manual stations into fully automated systems.

Savings potential

Reduce handling costs and increase profitability.

ARCHITECTURES

Use flexible architectures, precisely tailored to your testing requirements.

-

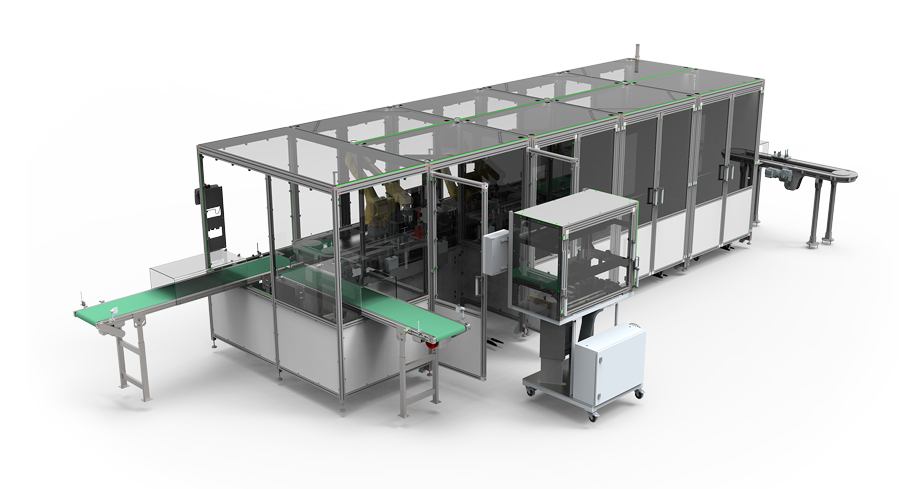

Fully automatic in-line systems:

Continuous testing lines for smooth and efficient processes. -

One-piece flow lines:

Continuous material flow with seamless transition between work steps. -

Manual stand-alone cells:

Modules can be used flexibly for specific testing tasks and variable quantities. -

Robot cells:

Versatile automation units for maximum precision and flexibility.

We support you in selecting the optimal architecture for your EOL testing system.

Test processes

Our flexible systems for EOL testing reliably cover all relevant testing processes.

Leak Testing

Reliable detection of leaks to ensure product quality.

Functional Testing

Ensure the performance of your products through comprehensive functional tests.

Insulation and resistance testing

Reliable verification of electrical functionality and safety.

Laser marking

Permanent labeling to ensure the traceability of your products.

Vision control

Precise optical testing for the highest quality standards.

Find out more about integrating these and other processes into your EOL testing.

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de