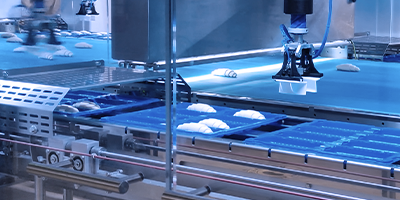

Manufacturing services

We manufacture your components to the highest standards of precision and complexity—from prototype to series production.

Your partner for precision components

Benefit from our expertise in the production of sophisticated machine components. With us as your outsourcing partner, you can implement your projects economically and successfully.

Ensure perfection

Take advantage of top-tier manufacturing expertise and cutting-edge technology—ensuring maximum precision, even in the most complex projects.

Increase your efficiency

Reduce your costs through our specialized and cost-effective end-to-end processes, giving you more room to focus on your core competencies.

Experience flexibility

Ensure planning security and quick response times through agile processes, a high level of in-house production and comprehensive material availability.

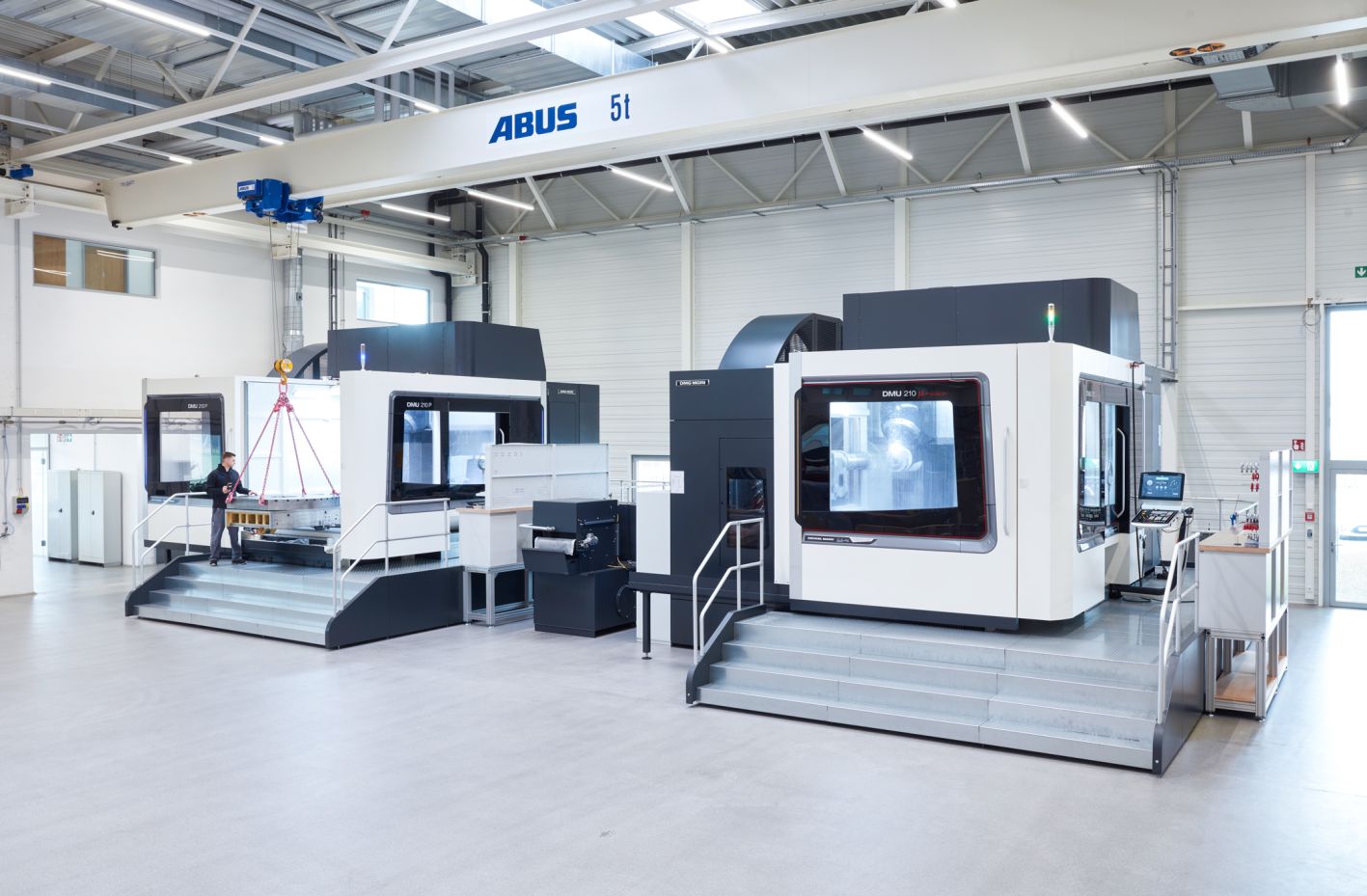

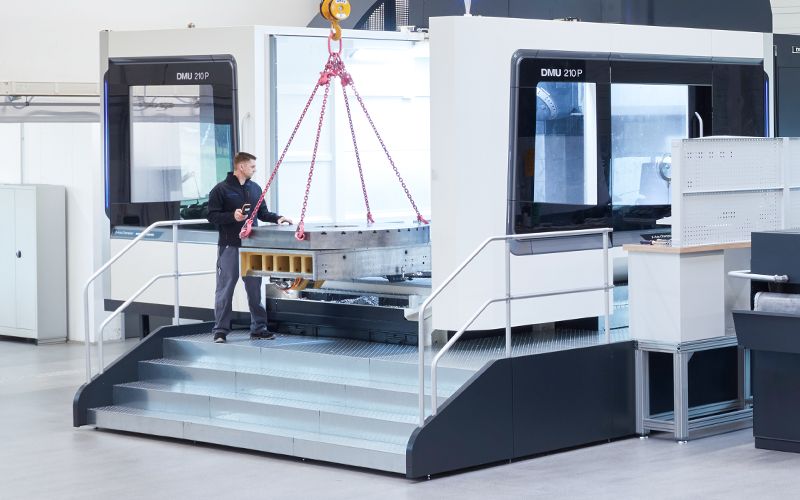

The benchmark for precision manufacturing

Our state-of-the-art machinery in a modern, air-conditioned production environment sets industry standards. Discover the technical possibilities in our machine lists.

Manufacturing techniques

Leverage our extensive range of manufacturing techniques to bring your precision components to life.

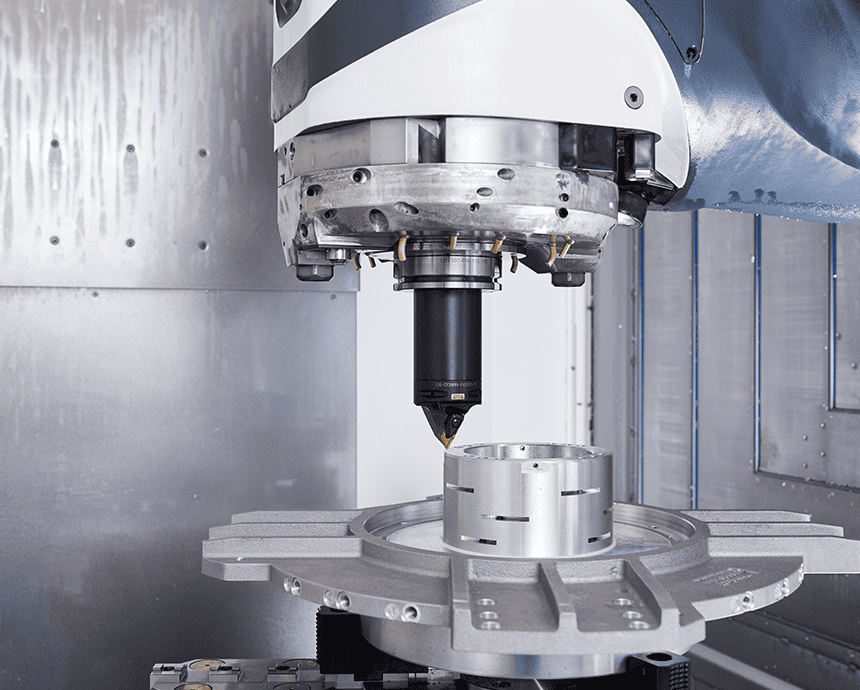

Our portal milling machines, such as the DMU 210?Precision, achieve micrometer-level tolerances with three times the precision of standard machines. With 5-axis simultaneous machining, temperature stability, and dynamic workpiece processing, we set standards in precision manufacturing.

With 3-, 4-, and 5-axis machining centers, we manufacture complex individual parts and 3D contours precisely and flexibly. Long travel paths and the combination of CAD/CAM systems and tool management ensure optimal results for demanding projects.

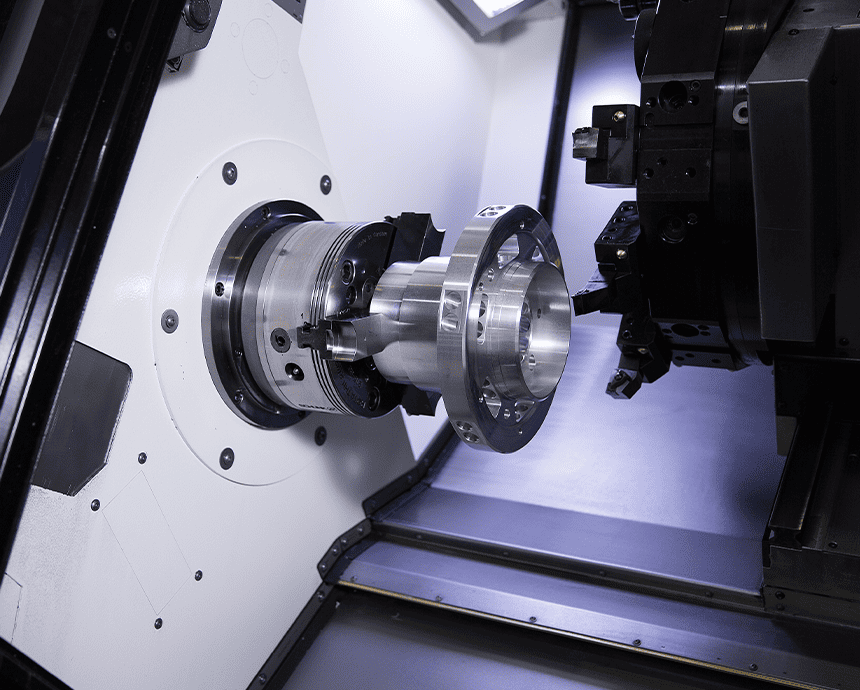

Our lathes with counter spindles, driven tools, and large Y-axis travel paths process workpieces up to Ø 800 mm and 2,000 mm in length. Innovative technologies such as deep hole drilling and hard machining ensure precision and efficiency.

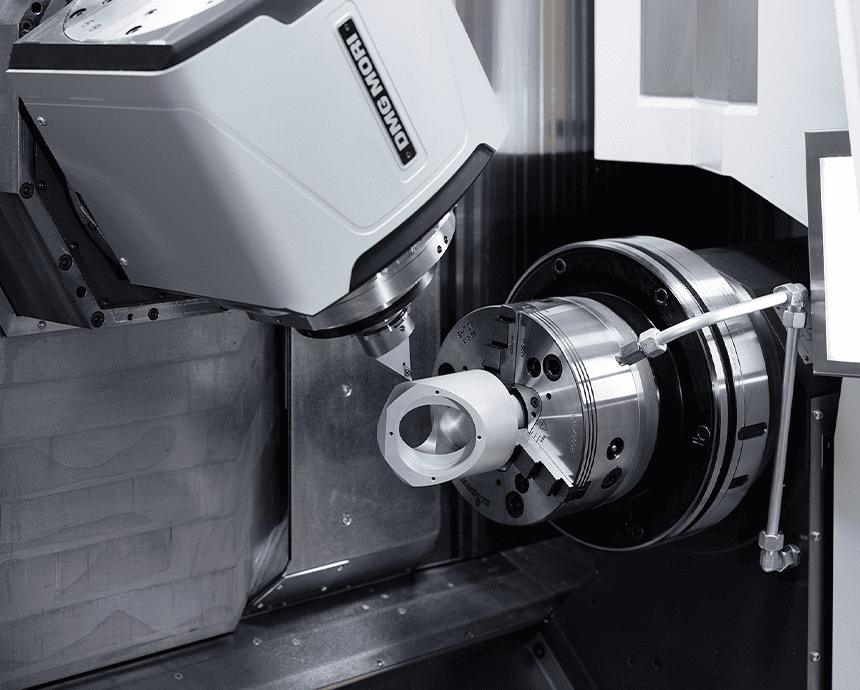

Our turning-milling centers enable µ-precise 6-sided complete machining in a single setup. Workpiece loading systems and advanced control technology ensure maximum productivity for highly complex components.

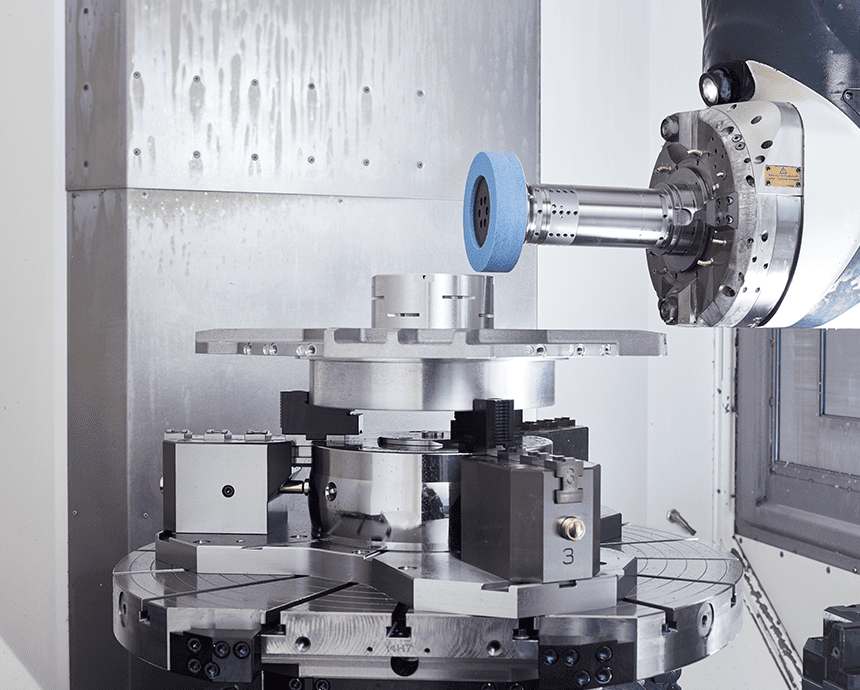

Integrating grinding technology into our milling-turning processes ensures excellent surface quality and dimensional accuracy. By machining in a single setup, we achieve the highest process security and stability.

Our grinding machines enable precise machining of hard-to-machine materials. From cylindrical, flat, and profile grinding to non-cylindrical machining, we meet the highest demands for dimensional accuracy and surface quality.

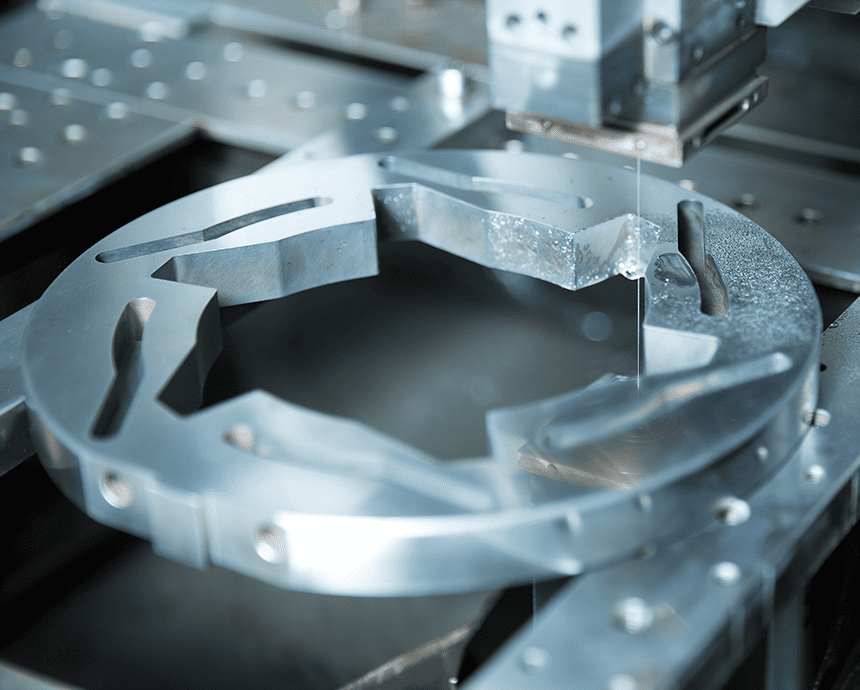

Our wire EDM machines produce intricate contours regardless of material hardness. With wire diameters from 0.05 mm and precise travel paths, we guarantee dimensional accuracy and quality.

Quality assurance

You can rely on state-of-the-art quality assurance technologies, such as our optical and tactile coordinate measuring systems in air-conditioned measuring rooms. With tailored measurement concepts such as form and positional testing, 3D scanning, reverse engineering, and component digitization, we ensure that your high quality standards are met.

In addition, we offer first article inspection reports (FAIR) for new parts and prototypes, as well as 3D coordinate measurements as contract measurement services.

Our quality assurance is certified according to DIN ISO 9001:2015.

Complementary technologies & services

Benefit from our extensive capabilities, with which we can optimally meet nearly all requirements.

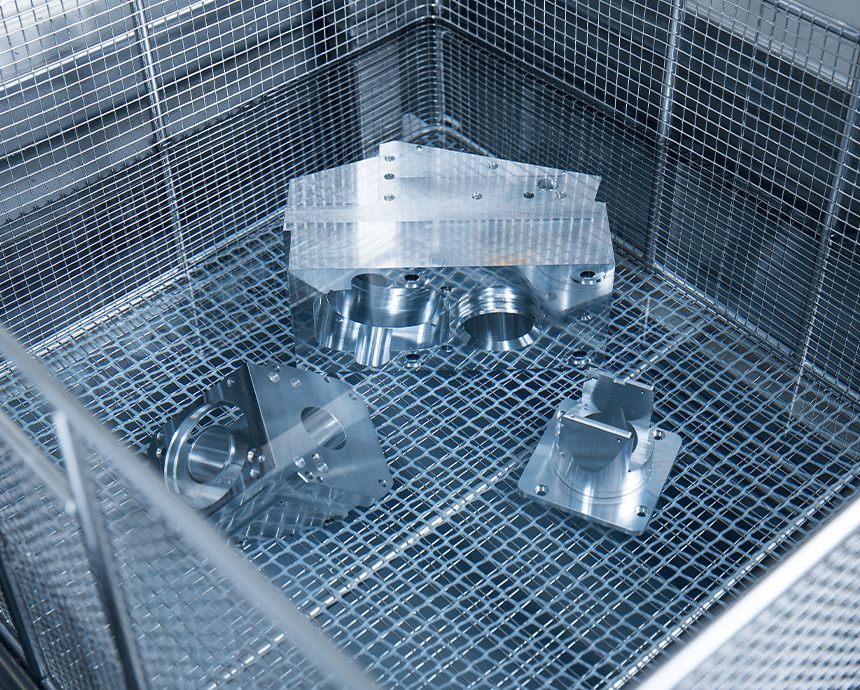

Our ultrasonic cleaning systems meet cleanroom requirements. Processes like UV testing and coolant cleaning ensure cleanliness and dimensional accuracy for the highest precision standards.

We use state-of-the-art laser marking systems to individually mark your components—from company logos to data matrix codes. Whether rotationally symmetrical or cubic, we guarantee precise and durable results according to your specifications.

Our TIG and MIG welding processes, as well as orbital welding, ensure durable and precise constructions made of stainless steel. Glass bead blasting and weld seam finishing complete the offer.

Our specialized CAM team combines many years of experience with the latest software to implement your design data efficiently and precisely. This is how we consistently achieve complex workpiece shapes and challenging machining tasks with the highest level of quality.

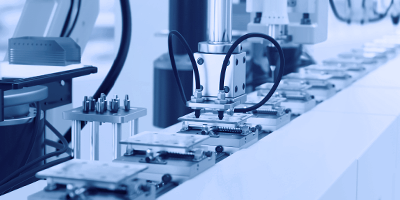

With our assembly expertise, we are expanding our portfolio to include mechanical, pneumatic, and electrical assembly services—from subassemblies and ready-to-install components to complete machines. This enables us to offer you tailor-made solutions from a single source—efficient, economical and of the highest quality.

Additional information: Assembly services

With our network of specialists, we are expanding our portfolio to include processes such as surface and hardening treatment, die-sinking EDM, laser cutting, and coordinate grinding. This enables us to offer you comprehensive solutions from a single source.

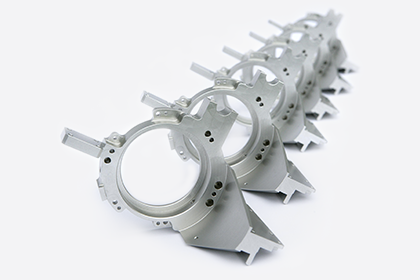

Components that will win you over

Bring your ideas to life with us—your partner for the high-precision and cost-effective manufacturing of complex prototypes, machine components, and 3D molded parts.

Prototyping

We guide you from concept to finished prototype—with tailored design plans, advanced CAD/CAM programming, and continuous cost optimization for precise and efficient solutions.

Machine components

From planning to delivery

Let us guide you step by step to your optimal solution—efficiently, transparently and reliably.

Consulting and analysis

Preparing quotes

Simulation and planning reliability

Manufacturing and quality control

Delivery and implementation

Globally positioned,

locally specialized

With an international presence and site-specific specialisations, we offer customised manufacturing services at strategic locations.

ZELTWANGER MASCHINENBAU GMBH

Contract manufacturing of high-precision, complex components, assemblies and systems.

ZELTWANGER CNC MANUFACTURING LP

Outsourcing partner for sophisticated components and assembly services.

ZELTWANGER AMT S.R.O.

Manufacturing partner for stainless steel welding assemblies, parts production and assembly.

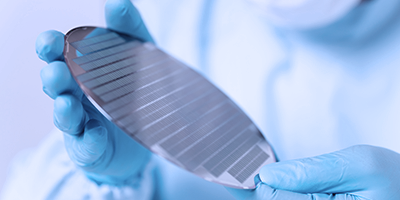

Industry Sectors

With our advanced solutions, we are the ideal partner in industries with the highest standards of progress, precision and quality. What our customers have in common: Like us, they are among the technology and innovation leaders in their fields.

Pharma and Lifesciences

Automotive and electromobility

Packaging industry

Battery manufacturing

Medical technology

Semiconductor manufacturing

General manufacturing industry

Optical industry

Food industry

Contact

Jaro Zeltwanger

Division Manager

ZELTWANGER Maschinenbau

+49 7071 3663-101

vertrieb.mb@zeltwanger.de

Simon Schmid

Sales

ZELTWANGER Maschinenbau

+49 7071 3663-101

vertrieb.mb@zeltwanger.de

Stefan Peinitz

Sales

ZELTWANGER Maschinenbau

+49 7071 3663-101

vertrieb.mb@zeltwanger.de

ANY MORE QUESTIONS ON THE SUBJECT?

We look forward to your inquiry and will be happy to advise you

on your

processes and requirements.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de