Leak Testing Solutions

Automatable, scalable, efficient: customized solutions for leak testing with air and tracer gases.

INNOVATIVE LEAK TESTING FOR QUALITY AND EFFICIENCY

Ensure the quality of your products and create efficient production processes. With our innovative and automatable solutions for leak testing with air and detection gases, you can reliably identify leaks and thus promote optimum product and manufacturing standards.

What makes us your ideal partner:

Holistic

Testing technology, accessories, automation, knowledge transfer and support: We provide you with the complete range of leak testing from a single source, also as a turnkey solution on request.

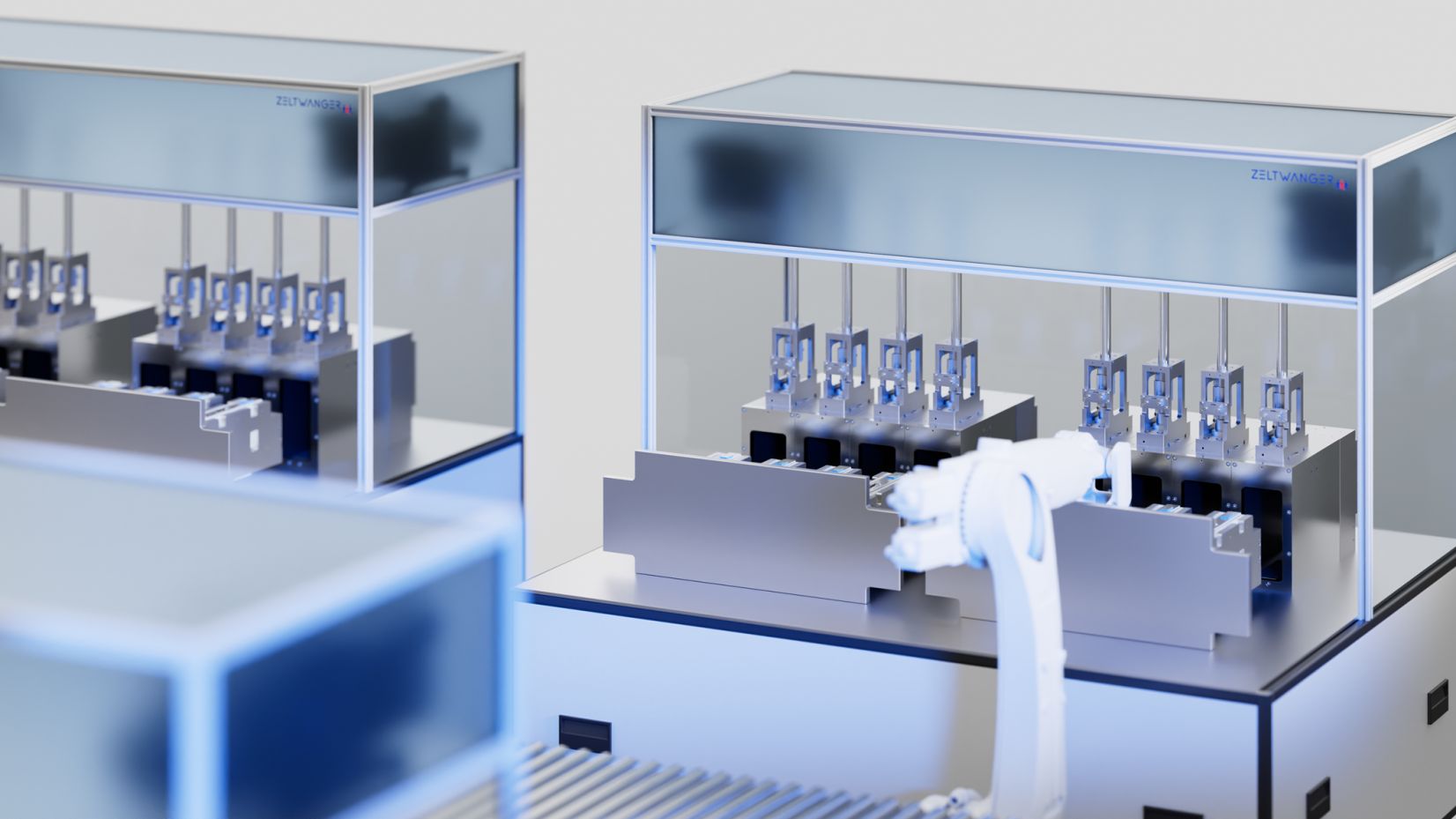

Scalable

From pre-testing to series production: with our scalable solutions and services, we support you on your way into the future, true to the motto “From Lab to Fab”.

Customizable

Leakage rate, geometry, test pressure, environmental factors – every test item has individual requirements. The same applies to your processes. Together we develop the optimum solution.

All test methods with air and tracer gases

We offer all common leak testing methods with air and tracer gases. Our team is happy to assist you in determining the optimal testing method for your requirements.

TEST METHODS WITH AIR

-

Mass flow method (MF)

-

Flow method (RD/DF)

-

Pressure change method (RD/AD)

-

Differential pressure method (DD)

-

Accumulation pressure method (SD)

-

Bell testing (RD/GP)

TEST METHODS WITH TRACER GASES

Leak testing with tracer gases such as helium or forming gases is suitable for particularly low leak rates and for the precise localization of leaks.

-

Sniffer testing

-

Accumulation method

-

Vacuum integral method

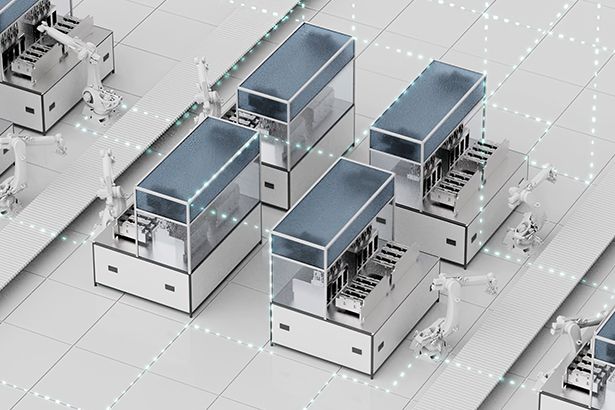

Leak testing and automation

Rely on a competent partner and implement projects successfully and efficiently. We offer you the entire spectrum of leak testing and its automatization.

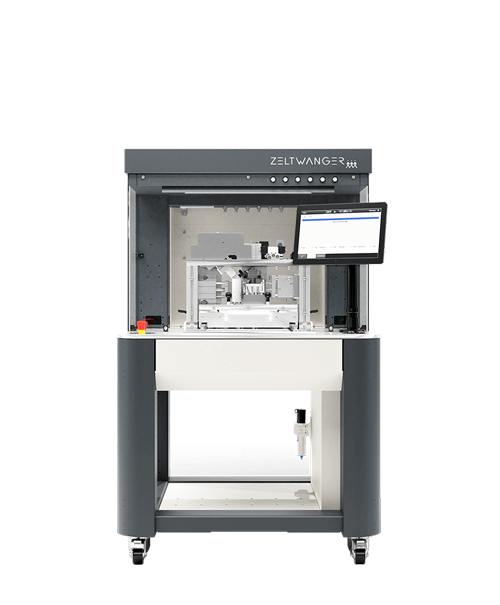

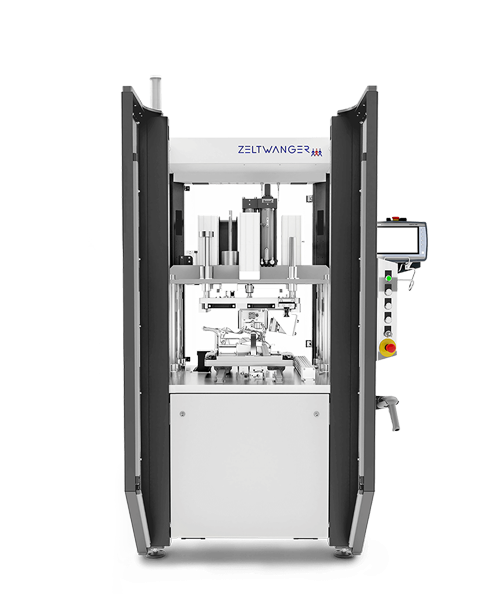

High-end leak testing technology

Rely on modern leak testing technology. Whether it is a measurement module, leak tester or test bench, our in-house software, application and sensor development means we can offer sophisticated and future-proof test technology.

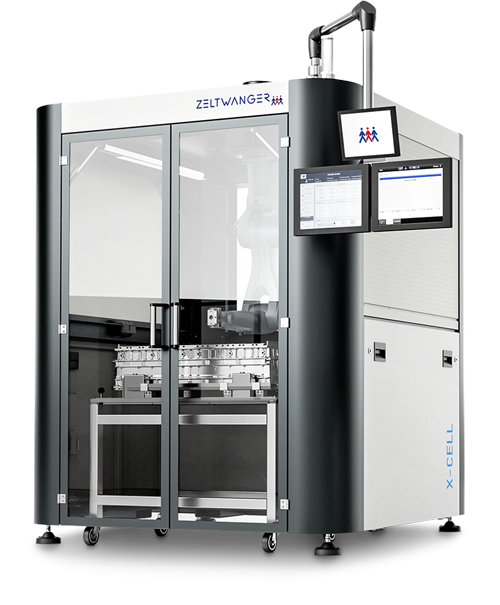

Efficiency thanks to automatization

More efficiency and precision – take advantage of the benefits of automation. In addition to the core process of leak testing, we also automate related processes such as handling, product marking for traceability and joining.

Easy integration into your systems

Thanks to intelligent interfaces and flexible software, our solutions for leak testing and automatization can be integrated into existing production infrastructures and connected to higher-level control systems, such as MES and ERP.

Reliable sealing concepts

Reliably sealing adapters and adaptations are an important prerequisite for dependable testing results. No matter how complex your test object may be, we manufacture custom-fit, high-precision testing tools.

All-round service for your projects

Our team provides you with personal and comprehensive support—from development to commissioning and beyond. We are at your side with support, maintenance, retrofitting and calibration services.

SAVE TIME AND MONEY

Benefit from standardization. In many cases, our flexibly configurable system platforms provide the ideal basis for efficient, automatable leak-testing processes.

Solutions for industries

and applications

Leak testing is a crucial aspect of quality assurance in all manufacturing industries.

We develop the optimum solution for every application.

E-mobility and battery production

Leak testing of battery cells, battery modules and battery packs

Medical technology and medical devices

Leak testing of medical single-use products, endoscopes and device components

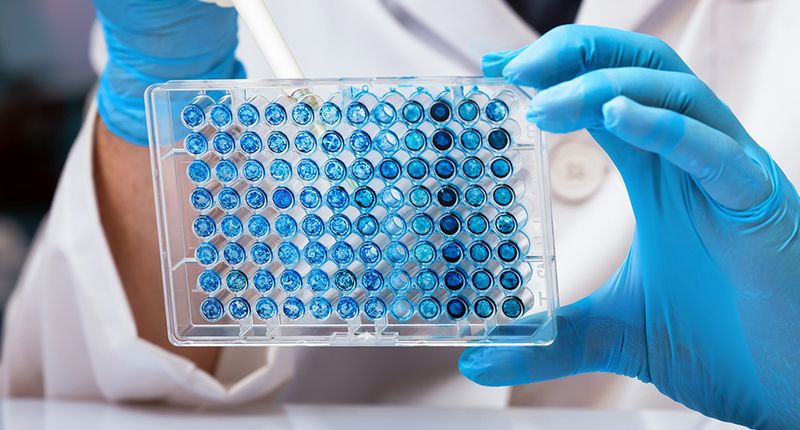

Biopharma and life sciences

Integrity testing of single-use systems (SUS), such as bioprocessing bags

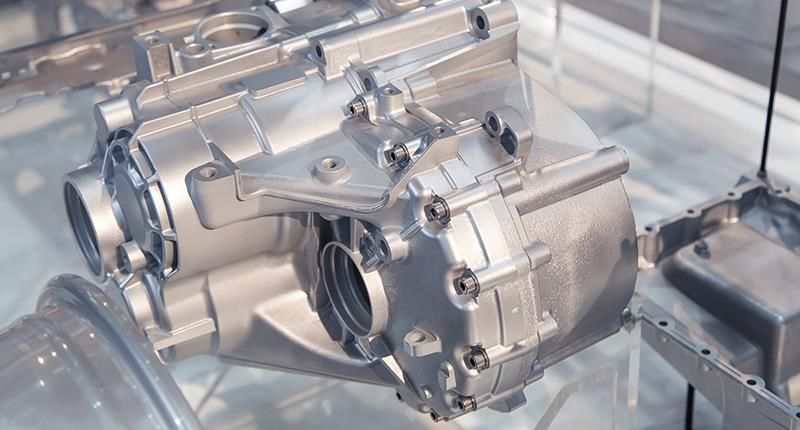

Die casting

Leak testing of die-cast products such as engine, transmission and pump housings

DISCOVER PROFESSIONAL LEAK TESTING

Are you working on a leak testing project?

Contact us for expertise on testing procedures, technologies and equipment.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationCONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de