SAFETY AND EFFICIENCY FOR HYDROGEN TECHNOLOGIES

Hydrogen technology plays a significant role in the energy transition. The leak tightness of fuel cells and electrolyzers is a crucial success factor for their safety and efficiency. As a leading provider of leak testing technology and a long-standing development partner of numerous automotive manufacturers, we offer innovative testing systems for bipolar plates, fuel cell stacks, fuel cell systems, and electrolyzers.

Application examples

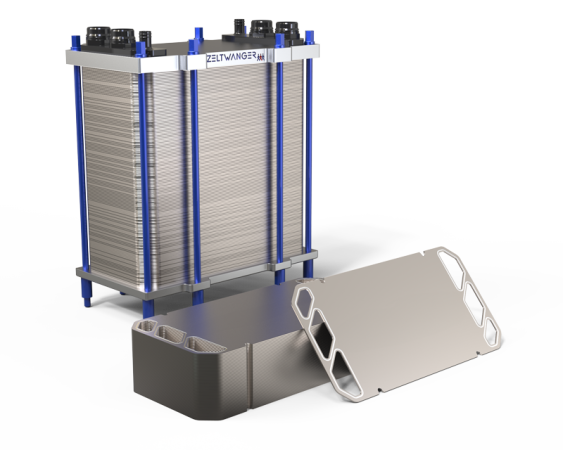

Bipolar plates

Small volumes, minimal leakage rates to be detected and a large number of cavities to be tested are among the challenges in leak testing of bipolar plates. By incorporating sophisticated techniques such as the use of the relative pressure method in conjunction with an external valve block or integrated vacuum testing with tracer gases, we are able to ensure reliable test results.

We also offer Testing as a Service for bipolar plates.

Fuel cell stacks

Fuel cell stacks have to be highly leak-proof. In order to reliably test these complex systems, various testing methods such as air mass flow are used. To locate leaks with pinpoint accuracy and to ensure a high degree of reproducibility, precisely guided sniffer tests using tracer gases like Helium are applied. Furthermore, we can implement additional steps such as compressing the stacks and marking detected leaks.

Leak testing of fuel cell systems

Leak testing as a service for bipolar plates

Our bipolar plate testing service offers expert leak testing for prototypes and small runs, using advanced testing methods to ensure the reliability and performance of your components.

Key Advantages:

-

Streamlined launch: No large upfront investment needed.

-

Fast results: Keep your project on track with efficient testing.

-

Expert support: Focus on development while we handle the testing.

Technical Specifications:

-

Testing methods: Latest methods; simulate real operating conditions.

-

Leak rates: Down to 1 x 10-6 mbar · l/s.

-

Component sizes: Test objects up to 650 x 750 mm.

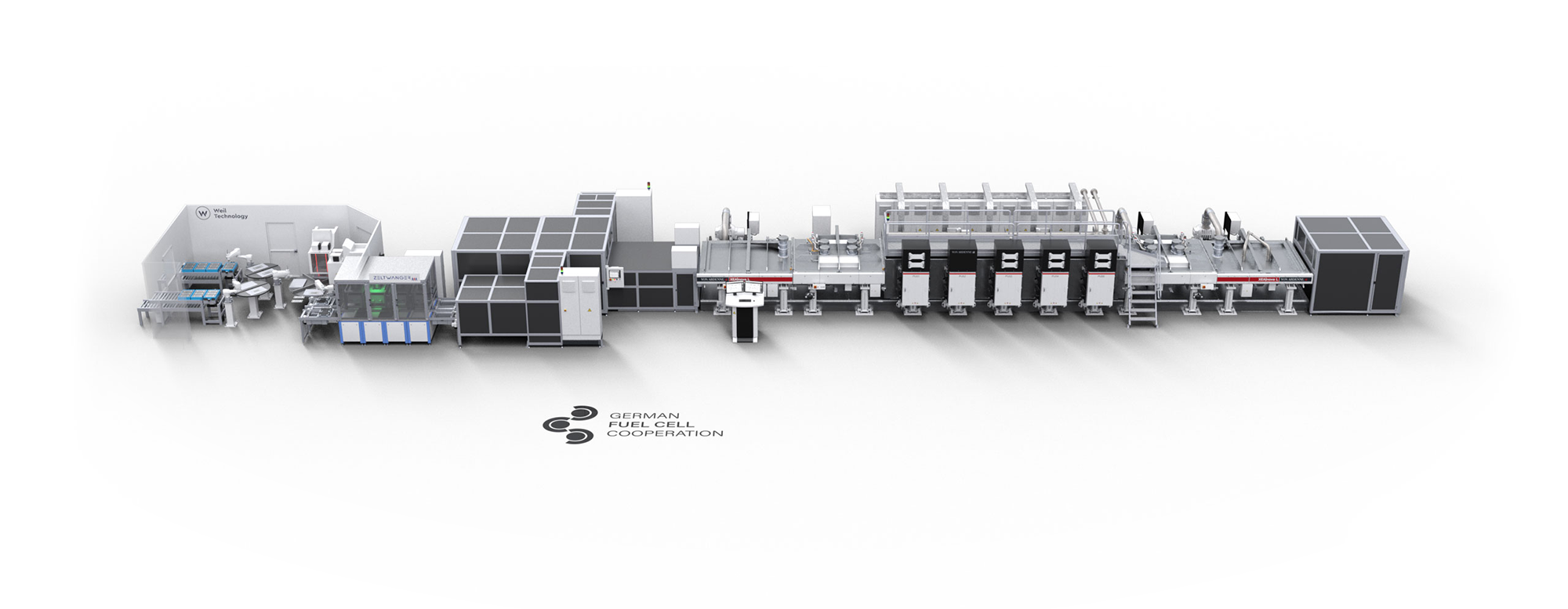

German Fuel Cell Cooperation

We are a member of the German Fuel Cell Cooperation, your partners for manufacturing equipment – from metal strip to fuel cell or electrolyzer stack.

How do you efficiently produce the fuel cell or electrolyzer of the future? VON ARDENNE, Weil Technology and ZELTWANGER have asked themselves this question together. Benefit from the knowledge and expertise of the three companies at every step in the process chain.

Discover professional leak testing

Are you working on a leak testing project?

Contact us for expertise on testing procedures, technologies and equipment.

You are currently seeing a placeholder content of HubSpot. To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More informationWhat makes us your ideal partner:

Holistic

Testing technology, accessories, automation, knowledge transfer and support: We provide you with the complete range of leak testing from a single source, also as a turnkey solution on request.

Scalable

From pre-testing to series production: with our scalable solutions and services, we support you on your way into the future, true to the motto “From Lab to Fab”.

Customizable

Leakage rate, geometry, test pressure, environmental factors – every test item has individual requirements. The same applies to your processes. Together we develop the optimum solution.

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de