ZELTWANGER Maschinenbau

Your outsourcing partner for manufacturing services and assembly

ZELTWANGER Maschinenbau is one of the leading outsourcing partners in Germany with outstanding expertise in the areas of highly complex machining, module assembly, and complete assembly.

Our passion for technology is what drives us. This is why we are the perfect long-term partner for contract manufacturing for our customers. This allows you to concentrate on your core areas of expertise.

From production and procurement through to final assembly and from prototypes through to series machines – we support you throughout all processes and help you find the perfect solution.

Download our machine list to get an initial overview of what we can do for you.

Our range of services:

Contract manufacturing & assembly services

ZELTWANGER Maschinenbau is a strong partner for services that involve precision manufacturing of challenging machine components and modules.

Contract manufacturing by ZELTWANGER – a complete solution from a single source.

Production of components

- Prototypes

- Machine components: Single parts, small-scale production, series production

- 3D molded parts

Assembly service

- Taking over the entire process

- Module assembly

- Complete machine

assembly

Process support

- Cost optimization

- Design advice

- Material selection

- Production advice

- Quality assurance

Outsourcing your module procurement to us comes with the advantage of simplifying many of your process steps.

-

Just one order

-

Simple deadline tracking

-

One contact person

-

Just one goods receipt process

-

Reduction in storage costs

-

Shorter assembly and lead times for you in-house

-

Reduction in procurement and personnel costs

-

Long-term partnership

-

Documented quality

-

Time to concentrate on your areas of expertise

-

Reduction in investment and capital commitment

We work with these technologies

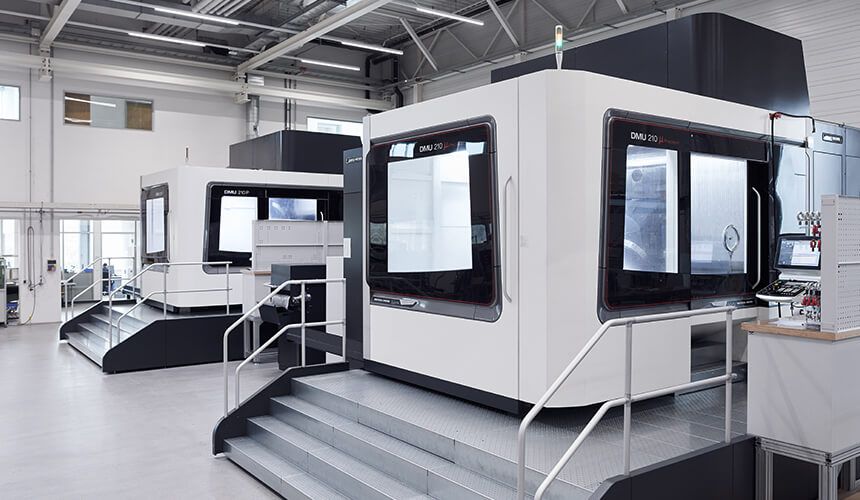

High-precision machining

One of a kind:

We facilitate extremely high-precision machining of components with our DMU 210 μ-Precision portal milling machines with positioning accuracy of up to four µm and DMU 210 P with an accuracy package with position tolerance of eight µm across the entire work area.

Parts weighing up to eight tons can be machined with an exceptional dynamic range.

CNC milling

In cubic machining, we use the latest 3-axis, 4-axis, and 5-axis CNC machining centers without exception.

The CAD/CAM system with sophisticated tool management means that complex single parts and 3D contours to be machined with maximum precision.

We achieve a very high vertical depth of production and flexibility in relation to the size of the parts to be manufactured.

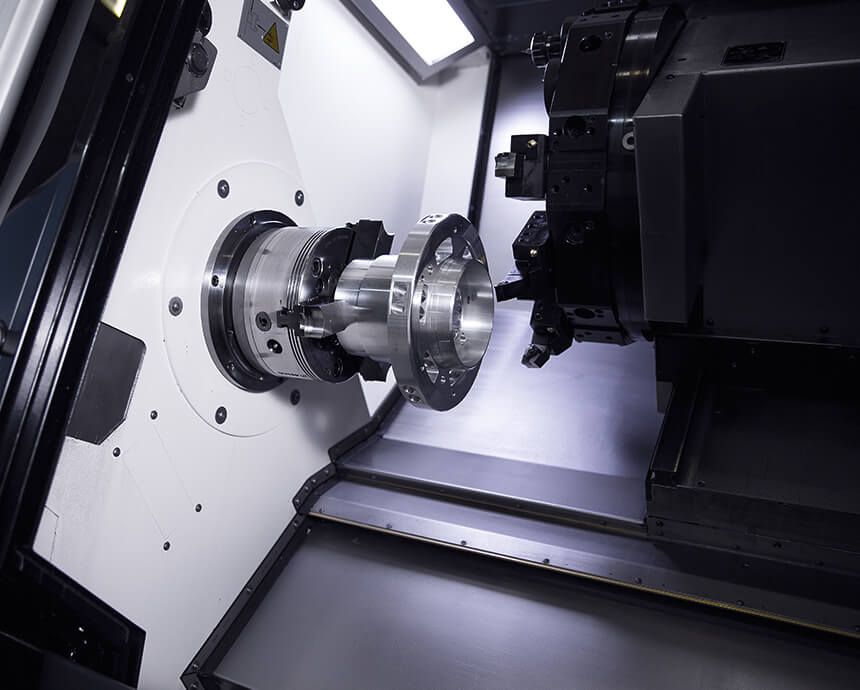

CNC turning

We use the latest turning and milling technologies for rotationally symmetrical machining.

Our CNC lathes have counter spindles and a long Y travel. This means that even parts with a diameter of up to 800 mm and a length of up to 2,000 mm can be manufactured.

Modern tool technologies mean we can offer hard machining with CBN, aluminum machining with PCD, or deep hole drilling.

Milling/turning/grinding center

For an excellent surface finish and dimensional quality, we incorporate grinding into the milling/turning technology.

We integrate grinding processes in a single setup using our DMC FDS “duoBLOCK” milling/turning/grinding center.

We guarantee high size and dimensional accuracy as well as excellent process stability with grinding finish machining.

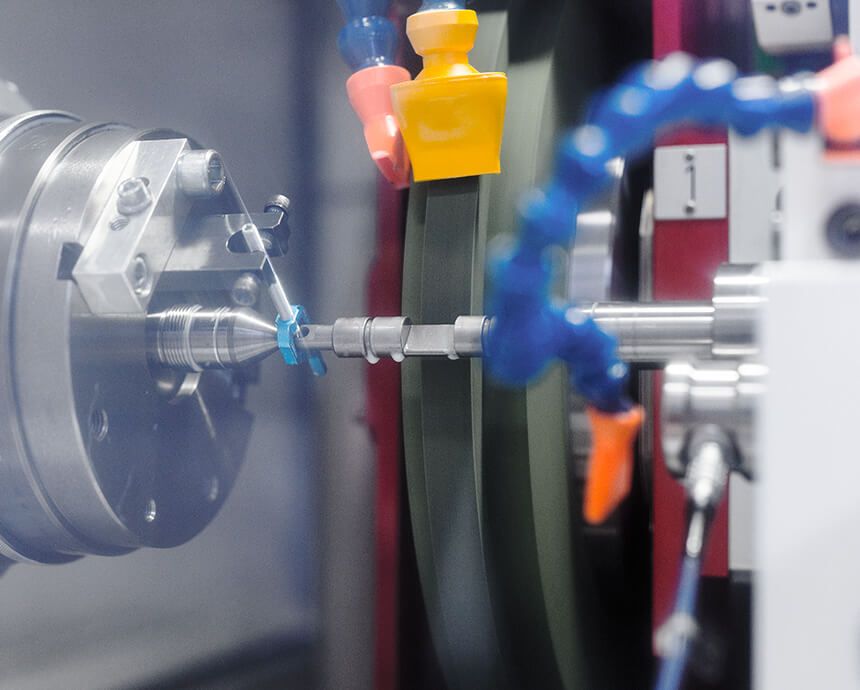

Round and flat grinding

We use our grinding machines wherever there are high demands for dimensional accuracy, size accuracy, and high surface quality in the micro range, or when hard-to-machine materials must be processed.

We can grind round (outside and inside) and flat with high precision. There are also options for non-circular grinding and profile grinding.

Wire EDM

The advantage of wire EDM is the ability to form even the most delicate contours. We guarantee the highest degree of dimensional accuracy and size accuracy.

The hardness of the material to be machined is irrelevant. With wire EDM technology, any electrically conductive material can be machined with high precision.

Quality assurance

Our quality assurance, which is certified according to ISO 9001:2015, is characterized by tried-and-tested and standardized production processes and many state-of-the-art measuring devices.

We develop an individual measuring concept for each component and carry out the measurements in-house. For this we have state-of-the-art measuring technology from Zeiss at our disposal – from the initial sample test report and the form inspection to curve and free-form surface scanning and reverse engineering including digitization.

Over 50 highly modern machine tools are available for your orders across an air-conditioned production space measuring 11,000 square meters.

Our machine list can tell you more about our areas of expertise.

ZELTWANGER Maschinenbau areas of expertise

We offer you a long-term partnership in contract manufacturing. Our service is based on an intense and transparent relationship of trust.

We support you throughout all processes – faster, more effectively, and more competently than our market competitors.

We guarantee short lead times, even with a large order volume.

What’s important to us at ZELTWANGER Maschinenbau

Highly complex parts, difficult requirements, short delivery times – we are a team that finds the right technical solution with passion and enthusiasm. In order to guarantee maximum quality, we invest in all areas:

- In highly qualified employees: They receive continuous training.

- In our wide range of high-tech machinery.

- In our working methods: We have independent, process-focused teams in the place of complex, time-consuming management structures.

- In partnership in action: We lighten your load and support you with our specialist knowledge and production options. This leaves you to concentrate on your core areas of expertise.

Do you have any questions?

Our service team is there to help. We are looking forward to hearing from you.

Find out more about our range of services here.

Simon Schmid

Sales

ZELTWANGER Maschinenbau

+49 7071 3663-101

vertrieb.mb@zeltwanger.de

Tobias Maisch

Customer service

ZELTWANGER Maschinenbau

+49 7071 3663-101

support.mb@zeltwanger.de

- Simon Schmid

- Sales

- +49 7071 3663-101

- vertrieb.mb@zeltwanger.de

- Tobias Maisch

- Customer service

- +49 7071 3663-101

- support.mb@zeltwanger.de

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de