ENSURING SAFETY AND PERFORMANCE OF BATTERIES

Leak-tightness is an important requirement for the safety and performance of battery systems. With reliable solutions for leak testing using air and tracer gases, such as helium, we support you in quality assurance for battery cells, battery modules, battery packs, and their components.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationAutomated solutions for leak testing using the example of battery cell testing.

Solutions for leak testing of battery systems

Leak testing of battery cells

Whether cylindrical, prismatic or in pouch form, we offer suitable solutions for reliable leak testing of battery cells. Depending on the requirements, various test methods such as helium vacuum leak testing or the electrolyte detection method are used.

Renowned battery cell manufacturers rely on ZELTWANGER‘s leak testing technology – from prototype testing to mass production.

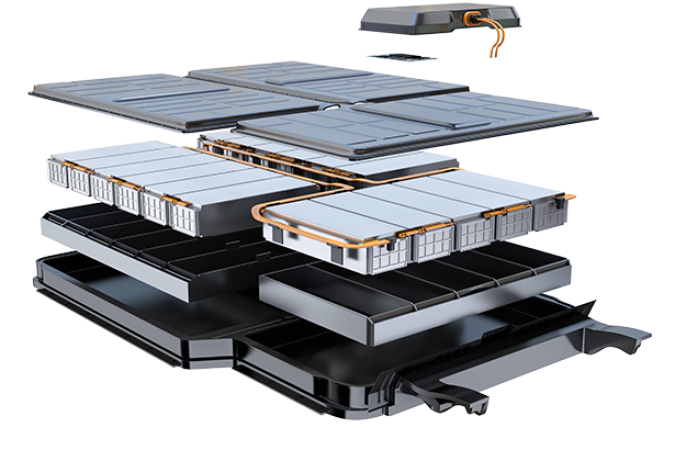

Leak testing of battery modules

and components

A battery system, consists of many individual components and assemblies that have to be checked for leaks. This includes battery modules, the cooling system, high-voltage connectors, pressure compensation elements (DAE), and enclosure components such as the battery tray, the battery cover, and other attachments. We also offer the appropriate leak testing solutions using air and tracer gases for these components.

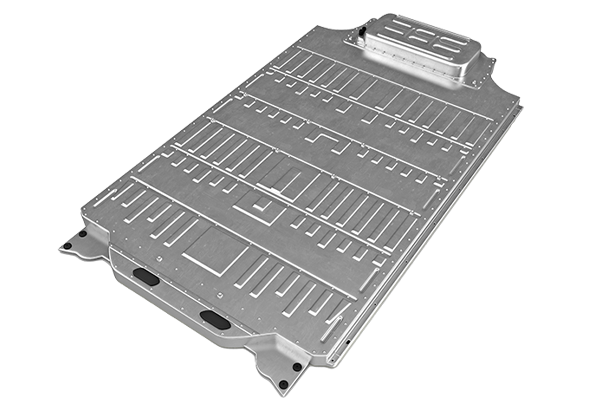

Leak testing of battery packs

Mounted battery packs must meet the highest requirements for leakage. The end-of-line test ensures that no leaks remain undetected before the pack is installed in a vehicle. Depending on the size of the component, the required cycle time, and the leak rate, different testing methods are used, such as the mass flow method, as well as accumulation or sniffing tests with helium. With the sniffing test, leaks can be pinpointed precisely using a manually or robotically guided probe.

Consulting and development

Are you working on a battery project? We are more than happy to support you with our holistic approach, from component design and specification analysis to feasibility assessments and consultation on the ideal test method and setup for the job. Our experts are here to help you through each step of the process, from the prototype phase to mass production!

Solutions for efficient manufacturing processes

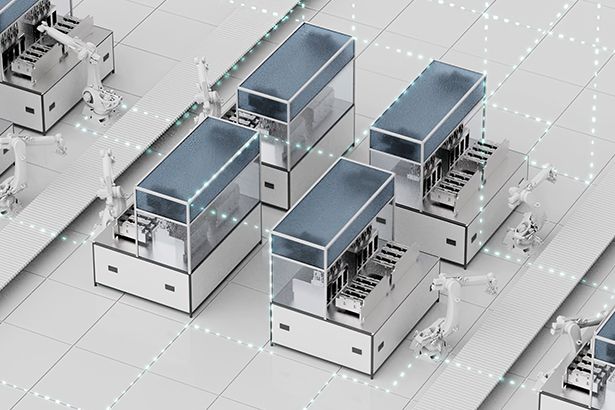

Automation

In addition to the core process of leak testing, we are also happy to integrate adjacent processes such as component handling or component marking. Our automation solutions tailored to your requirements promise the highest efficiency and precision.

INTEGRATION

We ensure optimal integration into complex production infrastructures through a variety of standard interfaces and options for custom connections to higher-level control systems, such as MES or ERP systems.

DISCOVER PROFESSIONAL LEAK TESTING

Are you working on a leak testing project?

Ask our experts about testing methods, equipment or procedures.

You are currently viewing a placeholder content from HubSpot. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWhat makes us your ideal partner:

Holistic

Testing technology, accessories, automation, knowledge transfer and support: We provide you with the complete range of leak testing from a single source, also as a turnkey solution on request.

Scalable

From pre-testing to series production: with our scalable solutions and services, we support you on your way into the future, true to the motto “From Lab to Fab”.

Customizable

Leakage rate, geometry, test pressure, environmental factors – every test item has individual requirements. The same applies to your processes. Together we develop the optimum solution.

CONTACT

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de

Contact

ZELTWANGER Holding GmbH

Jopestr. 3

72072 Tübingen

Deutschland

Tel: +49 7071 3663-301

Fax: +49 7071 3663-333

holding@zeltwanger.de